Dual Headstock Lathe

Dual Headstock Lathe

Functional Description :

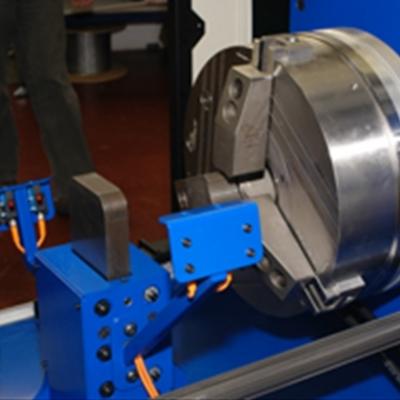

- For tube to tube pipe welding applications, this system utilises a pneumatic powered sliding headstock to provide to holding pressure between parts.

- Can be used with MIG, TIG and Plasma applications.

- Encoder feedback ensures constant weld width and penetration.

- Both headstocks are driven from a common drive shaft from a single motor.

- Each headstock can be used with either a conventional or automatically controlled pneumatic chuck.

- Levelling screw Jacks are fitted making the lathe capable of lifting total combined payload of 2000kg.

- Bespoke systems available.

- Designed to be used with the VBC IE 400 power source with the options of :

- Arc Voltage Controller

- Pulsed Wire Feeder

- Weaving Unit

- Magnetic Arc Deflector

Advantages:

- Component sizes from 25mm to 115mm outside diameter as standard. Other sizes available

- Strong fabricated main frame with 250mm between headstocks when fully open.

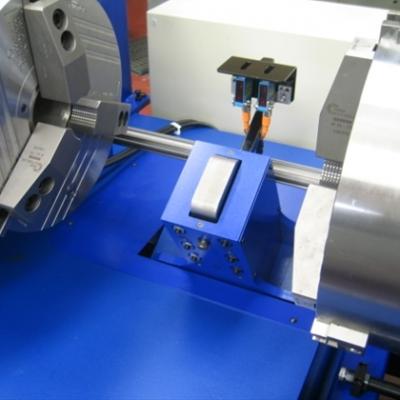

- Through beam photoelectric sensors detect the presence of the part at both the entry point to each headstock and the location at the weld position.

- Pneumatically controlled extending stop ensures that the parts are in the correct position prior to sliding headstock closing the parts together.

- Sliding arc screen rated at 500Amps with "screen closed" safety switch ensures the operator is protected from the arc.

- Plough ground rear support structure for mounting the AVC slide and wire feeder motor and spool.

- Fitted with stainless steel cone shaped chuck protectors to the rear of both turntables.

- Option of a split Upper and lower frame by four synchronized screw jacks to adjust the operating height