Series Two

Series Two

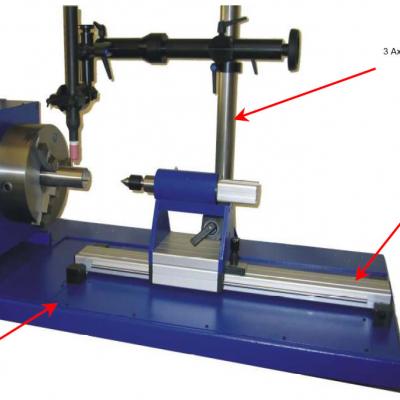

Series Two Welding Lathe

- Our mid-range welding lathe, Utilising the Model W Headstock with a variety of functional options. From on/off rotation and speed control, to fully programmable weldset interfacing.

- Suitable for TIG, Plasma and MIG welding applications.

- Simple to set up and use.

- The programmable speed can be accurately set within 0.01 RPM and maintained by encoder closed loop control during welding.

- When used with either the Interfaced controller, IE 160 or narrow bead InterPulse welders, the Series One Lathe can form part of an automatic welding system.

- Option of pendant sequence start / stop or where a Weld Cabinet is supplied, by door closure.

- 230 Volt 50 Hz operation (110 Volt optional)

Standard machine capacity:

- 500mm between centres, 350mm max diameter

- Bespoke systems and size capacities available

Advantages:

- Speed range 0.5 to 10.0 RPM as standard.

- Other speed ranges available on request.

- 200 or 400 Amp earth return brush gear with insulated 12 brass stud for connection to the weld set.

- 50KG weight capacity.

- Clockwise and counter clockwise rotation control.

- Complete with 2 or 3-axis Micro Torch Positioner.

- Can be rapidly repositioned at any location along the length of the lathe and locked into position.

- Supplied with Weld Torch Clamp.

- Can be fitted with either a 305mm faceplate,

- 160mm / 250mm 3-jaw or 4-jaw self centring chuck.

- Custom tooling also available.

- Option of Standard, Interfaced, or weldset controller configuration.

- The weldset controller provides program storage and keyswitch lock, preventing the operator adjusting preset welding parameters.

- Adjustable sliding tailstock which can be locked in any position along length of bedway.

- Quill extension controlled by either hand operated lever or ptional pneumatic cylinder.

- Quill stroke 40mm (100mm pnuematic version)

- Quill provided with MT2 Live Centre