Model B – Faceplate diameter 200mm, Vertical load 50kg

Model B – Faceplate diameter 200mm, Vertical load 50kg

The Manual and Automated Model B turntables have been designed using proven Instrument Engineering Bedford Turntable frame technology to meet the most demanding production requirements.

- Suitable for TIG, Plasma and MIG welding applications.

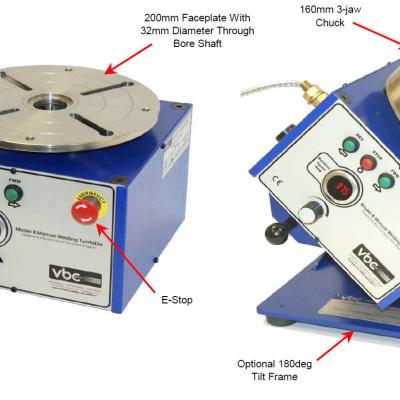

- Available in two versions. The Solid Shaft model, which has provision for a Shield Gas connection and Purge Tube, and the 32mm through-bore machine.

- Simple to set up and use.

- Both the Automatic and Manual controls include an LCD Display with 0.01RPM resolution, which can be set to the required speed before or during a weld cycle.

Manual Model B

- Designed for manual operation via the front panel switches,

- foot switch or variable speed foot pedal.

Automatic Model B

- Can form part of an automatic welding system.

- For example, as the Headstock of our Series 1 Welding Lathe.

- The Interfaced option provides an output to automatically start and stop a welder.

- Also incorporated is a pool delay timer, run on timer and an overlap counter set in degrees.

- Whichever unit you choose, you can be sure of unrivalled performance, reliability and durability from what has become recognised as one of the very best welding turntables available.

Advantages:

- Speed range 0.25 to 5 RPM as standard.

- Other speed ranges available upon request.

- 200 Amp earth return brush gear with insulated M12 brass stud for connection to the weld set.

- 50KG weight capacity in Turntable configuration, 25Kg as a Headstock.

- Clockwise and counter clockwise rotation control.

- Encoder feedback for accurate closed loop control.

- Can be fitted with either a 200mm faceplate, or a 160mm 3-jaw.

- The faceplate has concentrically scribed alignment circles and 4 radial clamping slots.

- Option of either Headstock brackets or 180 degree tilt frame.

- Option of additional foot switch or variable speed foot pedal (Manual Model B only)