HMS InterPulse Technology

HMS InterPulse Technology

The InterPulse gas tungsten constricted arc welding (GTCAW) process of the VBC Instrument Engineering is an advanced modification of conventional GTAW, using magnetic constriction and high frequency (20,000Hz) modulation of the arc waveform to produce a constricted arc and greatly reduce the overall heat input during welding.

The technique allows titanium and its alloys to be successfully welded outside of a vacuum chamber, without a trailing gas shield, and thus with far greater versatility and precision than conventional processes.

Working Principle of InterPulse Technology

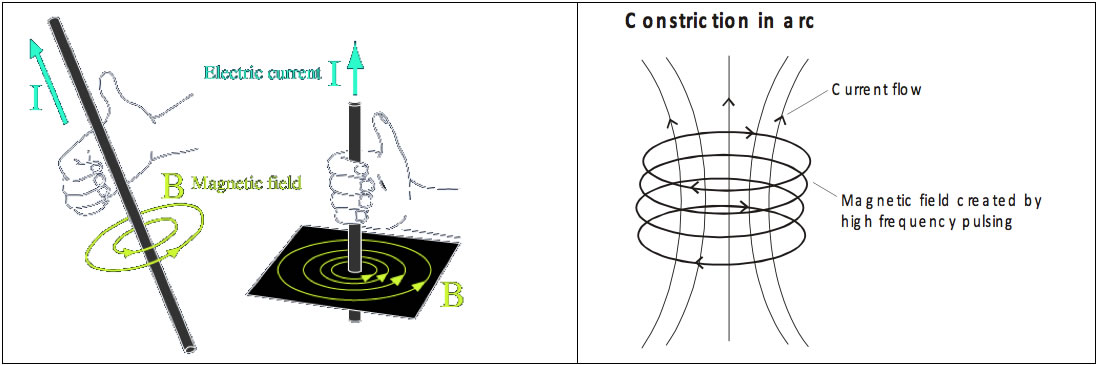

i. Right Hand Rule

The right hand rule is a useful mnemonic for visualizing the direction of a magnetic force as given by the Lorentz force law. The force is in the opposite direction for a negative charge moving in the direction shown.

ii. Arc Constriction

The weld arc is constricted by the magnetic field around the arc. The VBC InterPulse generates high frequency pulses, the relationships of which are programmable to alter the magnetic field of the arc, thus enabling the control of the constriction of the arc.

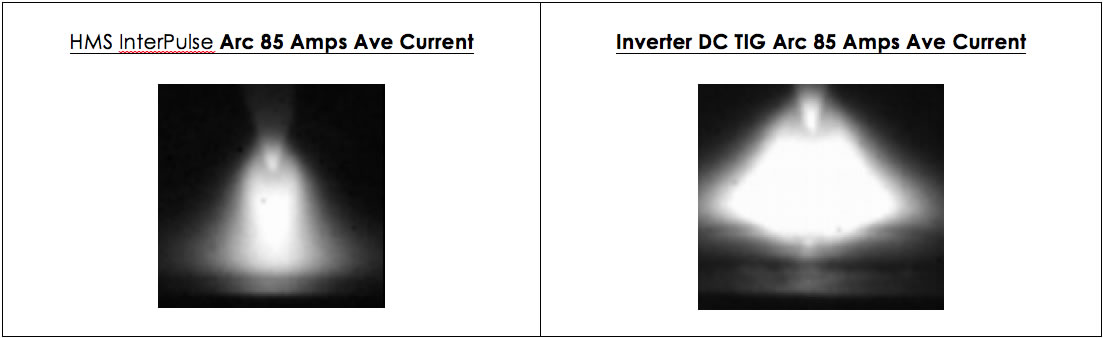

To illustrate the differences of the constricted arc of InterPulse technology against the conventional inverter power source, some pictures were taken during trails on titanium welds using a fast video camera.

The photos above clearly shows the constricted arc of the InterPulse which results in reduced heat input and heat affect zone which will greatly improve the weld quality comparatively with a Inverter TIG welding source.

The InterPulse process produce restricted heat input welds without the massively high cooling rates associated with electron beam and laser welding, which frequently lead to martensite formation, is a major advantage.

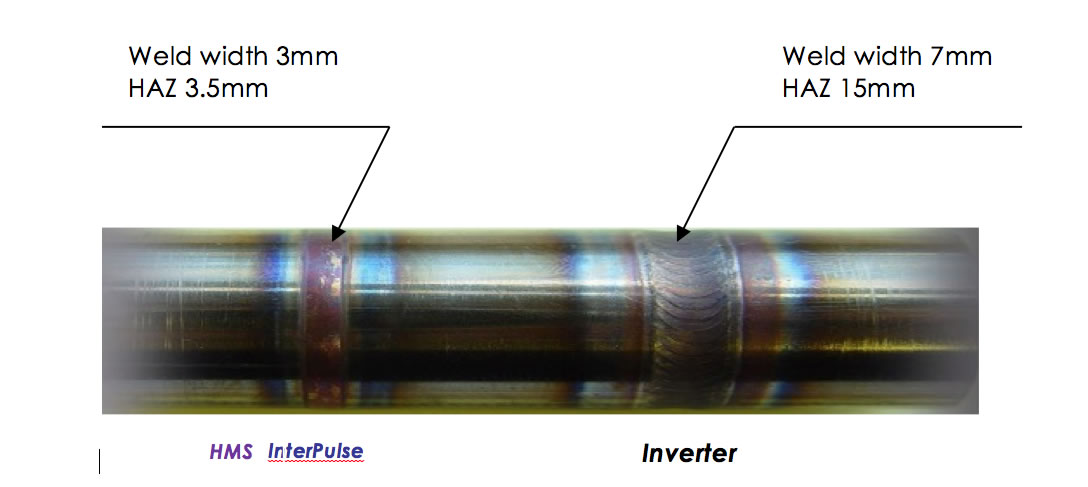

The picture below illustrates the superior weld quality of InterPulse vs Inverter welding source

The HMS InterPulse process is capable of high precision and control during welding because the advanced arc waveforms of the InterPulse can be tailored to control the macro and microstructures as well as textures and microtextures in the weld fusion zone. It is well known that mechanical properties of weldments are controlled by their microstructures.

In summary, HMS InterPulse is a comparatively easier weld process to control, with excellent capability to weld Nickel based super alloys and titanium materials and definitely more cost effective.

- HMS InterPulse Technology – DC Tig Welding

- Inverter Technology – DC TIG Welding