InterPulse 100Auto

InterPulse 100Auto

BRIEF INTRODUCTION OF INTERPULSE 100AUTO DC HIGH

FREQUENCY AUTOMATIC WELDING POWER SOURCE

InterPulse 100Auto is a new generation of low-heat input welding equipment. Nowadays, many difficult-to-weld metal welding requirements need to be completed. With the introduction of the famous DC fast frequency pulse (InterPulse) welding power source, this welding machine uses the latest welding arc. Control technology and InterPulse technology to help welders reduce heat input to improve welding quality to complete these complex welding tasks. The current universal argon arc welding machine uses the frequency conversion technology of the 1960s. Although it has been repackaged and renamed, it is essentially the same technology. Science and technology have made great progress in various fields, and metallurgical technology is no exception. The invention of new materials requires new welding techniques. The InterPulse 100Auto is designed for the welding requirements of new special hard-to- weld metals (pictures are for reference only).

Many materials that we need to weld daily in the aerospace and related industries, such as: CMSX-10, In738, 713, 625, C263, PK33, MAR-M 247, Rene 80, Rene 142 and high temperature alloys, etc. If you use our The InterPulse 100Auto welding machine can complete welding without an argon gas chamber and an argon gas hood, and at the same time, it can greatly reduce cracking and deformation.

InterPulse 100Auto is controlled by an ultra-fast power supply to control the arc characteristics, and is controlled by a mature and stable program to minimize the heat- affected zone and the width of the arc to create a precise electromagnetic field. These systems greatly improve the welding quality, enabling deeper penetration and narrower weld seams. The soft arc generated by the welding machine makes welding less dependent on the radiator, while the deformation is kept to a minimum.

The advantage of the DC fast frequency pulse (InterPulse) technology is that it enhances the arc strength or can have enough penetrating power in the case of low current input. This allows us to improve key welds that are very sensitive to heat input and still achieve full penetration. In addition, when we are performing filler wire welding, in the final microstructure, we can also find significant advantages due to the reduction of the molten pool. These excellent characteristics are especially remarkable when we are welding single crystal and oriented crystal products.

And InterPulse 100Auto provides an excellent and flexible integrated control interface

Machine Current Explanation

DC Current Explanation:

Delta current

Main Current

Background Curent

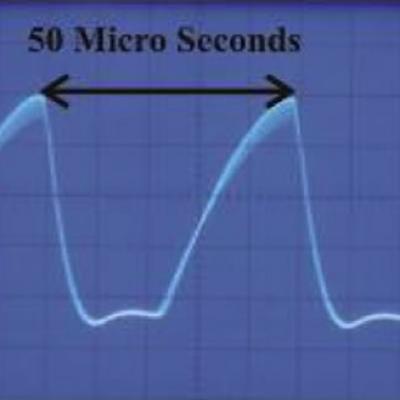

Delta current Waveform shown on right

MACHINE OPERATION MODES

STRAIGHT

PULSED

DELTA STRAIGHT

DELTA PULSED

The fast frequency pulse (InterPulse) and precision pulse of the fourth operation mode can achieve at least the following three superimpositions, which can meet different welding requirements

MACHINE PARAMETERS

InterPulse 100Auto TECHNICAL PARAMETERS Initial Current 0.1 - 60 A Upslope time 0.0 - 20.0 Seconds Downslope time 0.0 - 20.0 Seconds Final Current 0.0 - 100.0 Amps Final time 0.0 - 25.0 Seconds Pre purge gas 0.0 - 99 Seconds Post purge gas 0.0 - 99 Seconds Main Current 0.1 - 100 Amps Background Current 0.1 - 100 Amps Main time 0.01 - 5 Seconds Background time 0.01 - 5 Seconds Pulse Frequency 0 -50 Hz Interpulse Current 0.1 - 100 A Current Resolution 0.1 A InterPulse Frequency Range 0-20000Hz Cooling Method Water-cooled Duty Cycle 75A 100% Power Supply Requirements 单相 220 V 50Hz 22Amps